S Four Mile Run Sanitary Sewer Relining

Location

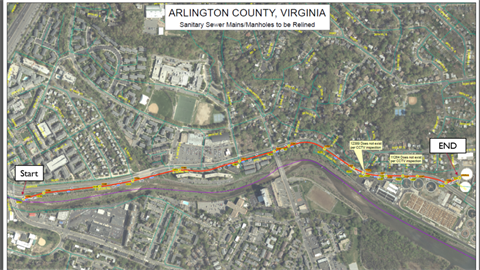

The project limits are: South Glebe Road from West Glebe Road to 3402 S Glebe Rd (Arlington's Water Pollution Control Plant)., Arlington, VA 22202 View Map

38.843846289861446, -77.0564512539757

The project limits are: South Glebe Road from West Glebe Road to 3402 S Glebe Rd (Arlington's Water Pollution Control Plant). ,

Arlington, VA 22202

The project limits are: South Glebe Road from West Glebe Road to 3402 S Glebe Rd (Arlington's Water Pollution Control Plant). ,

Arlington, VA 22202

S Four Mile Run Sanitary Sewer Relining

StatusNo Status

Proposed

About the Project

Sanitary Sewer

The sanitary sewer system is a key piece of infrastructure consisting of approximately 465 miles of sewer pipes and 13 lift stations. This intricate network exists to make sure that the wastewater that gets flushed every day from homes and businesses makes its way to the Water Pollution Control Plant (WPCP) where it’s properly cleaned and treated before being recycled back into the environment. Learn more about our sanitary sewer system.

Inspection

A CCTV inspection conducted in the fall of 2015 revealed that the sanitary sewer pipe had moderate-to-severe deterioration, including:

- Corrosion of concrete pipe

- Exposed aggregate

- Reinforcing steel exposed with rusting

- Infiltration, roots at the joints

- Small holes, void visible

CCTV inspection shows a small hole in the pipe.

Project Process

Rehabilitation Process

A temporary bypass will be installed to ensure no disruption in service. Due to the length of the project (5,900 linear feet), there will be some sections where the bypass is above ground. Manhole rehabilitation will follow the lining to completely seal the system from manhole to manhole eliminating infiltration and inflow.

Cured-In-Place Pipe Process

Cured-in-place pipe (CIPP) is a trenchless rehabilitation process used to repair existing pipelines using a resin (styrene) saturated felt tube.

Crews place a flexible liner into the existing sewer. Heated water is forced into the liner, pushing the liner tightly against the existing sewer walls. The heat causes the liner material to cure, creating a new pipe within the existing sewer that is free of cracks and holes. Crews then use pumps and hoses to re-route sewer flows, ensuring sanitary service to customers. The renewed pipe longevity is projected to last 50-70 years.

Example of CIPP using hot water. A boiler truck uses water to cure the liner with a circulation pump.

Project Timeline

Timeline: Summer 2018 to winter 2018/19.

Tentative construction timeline:

- Bypass pumps and pipes set up: 4 weeks

- Cleaning and lining each segment: 1 week

- 15 segments: totaling 15 weeks cleaning and lining

- Continuous process once liner is inserted: takes up to 48 hours for curing

- Bypass pumps and pipes demobilization and restoration: 4 weeks

Additionally, a 60 inch section of pipe on S Glebe Rd between S Arlington Ridge Rd and S Joyce St will be removed and replaced.

- New 54” junction box, 2 segments of 54” RCP pipe and 1 segment 12” will be installed

- Approximately 25 feet long

- Work cannot begin until bypass is installed/tested and running properly

- 45 estimated days for completion of work

- Work hours: 9am-5pm, Monday through Friday

- Relining work is not affected by the construction work

Photo Gallery